Manufacturing

This App Covers All Aspects of Manufacturing Processes

MRP + MES + PLM + Quality + Shop Floor + Maintenance

Transform Your Manufacturing Process with Our Cutting-Edge App

Discover seamless manufacturing management with our cutting-edge Manufacturing App.

Streamline your production processes, from planning to execution, with intuitive features designed to optimize efficiency and minimize downtime.

Simulated Operations in

Real-time

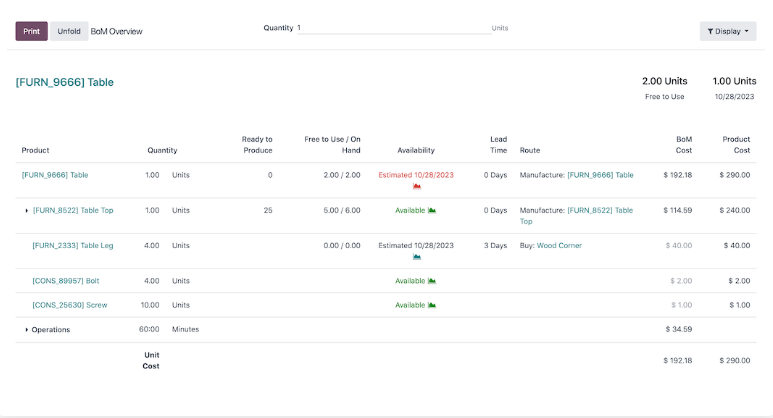

Simulate all your manufacturing orders with real-time capacity planning, available components, and cost control.

Get replenishment propositions just-in-time then choose how to fulfill parts: make or buy, sub-contract, deliver from another warehouse, etc.

Stay Ahead of Schedule with Planning

Gantt charts are useful because they show the activities and progress of a project.

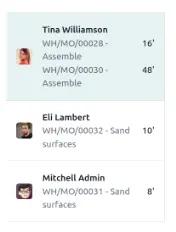

Schedule manufacturing orders and plan resources with finite capacity planning.

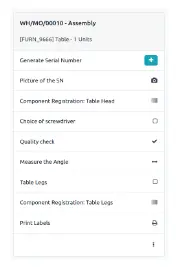

Capture Production & Components

Process orders, accelerate operations, and minimize input errors.

It works right out of the box and is blazing fast, and with no latency.

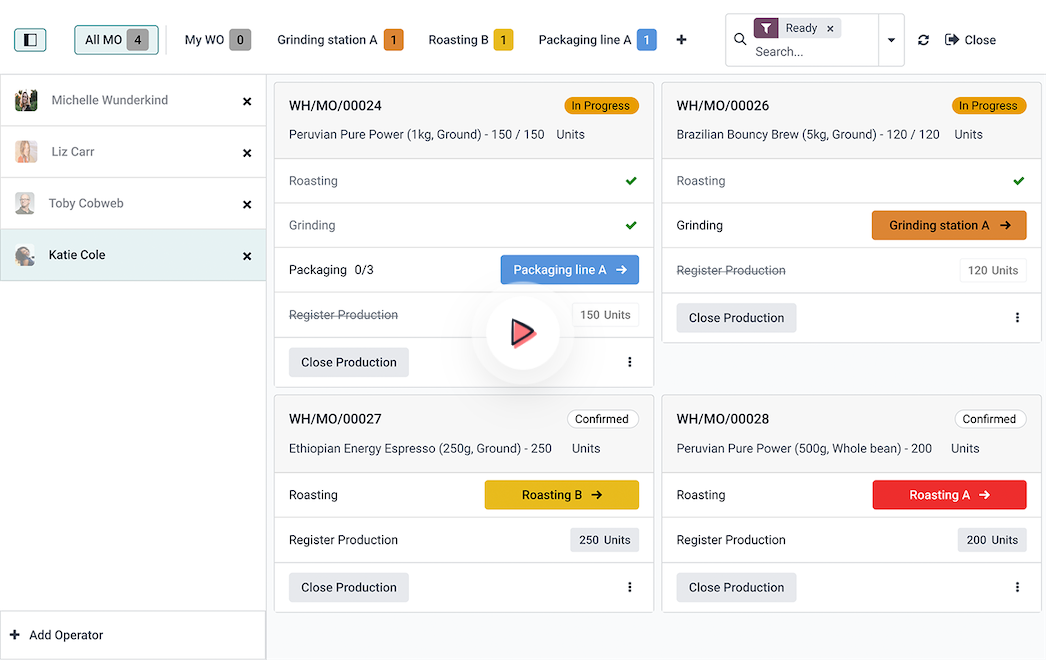

Embrace the Power of Our Paperless Solutions!

Streamline your manufacturing line with the shop floor app.

Work through the tablet-optimized dashboard, where you can organize workers, work-centers, worksheets, and quality tests.

Six Sigma

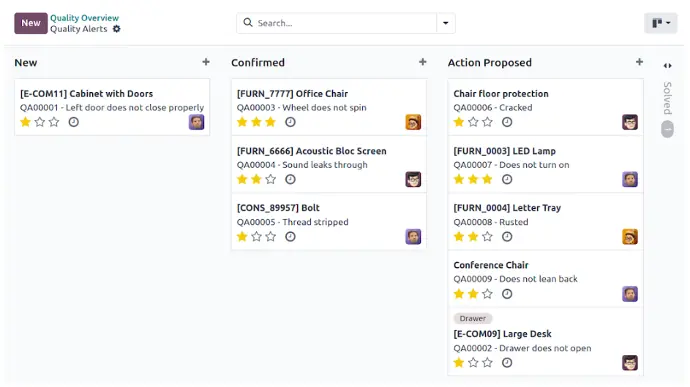

Six Sigma - It's a set of techniques and tools used for process improvement. Receive statistical analysis of quality issues, and set control point instantly available in the shop floor with instructions.

The employees can send feedback using the app if and when they notice waste in the manufacturing process. Ideas and information flow smoothly so the quality is uplifted to another level.

The Perfect Tool for Kaizen

Mastering Production Schedule

The Master Production Schedule (MPS) serves as a valuable tool for your Sales and Operations Planning (S&OP) meeting, facilitating the seamless alignment of sales objectives with those of the manufacturing department.

Powerful yet Simple

While SWiiB provides a comprehensive set of functionalities for the implementation of a cutting-edge manufacturing assembly line, it excels in user-friendliness, thus obviating the necessity for extensive employee training.

Up/Down Stream Traceability

Implement monitoring mechanisms, conduct batch manufacturing, or utilize serial numbers for seamless traceability of all operations at the click of a button.

Leverage by Products

Develop residual products through the integration of by-products into the bills of materials.